Achievements

EXPERIMENTAL RESEARCH ON DOUBLE-LAYER GRAVEL-PRE-COATED SCREEN

Ye Chengming1,2, Zheng Jitian2, Ran Defa2, Wang Jianzeng2

(1.

School of Engineering,

Abstract: With reliable effectiveness,

relatively lower price, and easy installing, gravel-pre-coated screen has

become the major screen used in wells in silt-fine-sand aquifers in many

countries. In the 1970s, steel-based and plastic-based gravel-pre-coated

screens were developed in

Key words: double-layer gravel-pre-coated screen; experimental research;

1 Introduction

Gravel-pre-coated

screen is made with filtering tube stick to certain grain filtering materials

by synthetic resin. It has mane advantages for complete well through using it

,such as increasing drilling efficiency, improving well completion quality, simplifying

well completion process, saving washing time ,as well as reducing the

danger of sand boil in the process of well using. Gravel-pre-coated screen is

one of the main well screen for silt-fine-sand aquifers in well abroad. In the

1970s, steel-based gravel-pre-coated screen were developed in

2 Study Methods and Procedure Summarize

The test study adopts mainly methods of single-double-layer gravel-pre-coated briquette indoor testing and compare testing analyze. The study procedure as follows:

a. Four types of filtering material(5-3mm,3-2mm,2-1mm,1-0.5mm)are selected according to performance request for filtering sand of gravel-pre-coated screen. The performance request for filtering sand of gravel-pre-coated screen is described in Table 1.

Table 1 Characteristic of Gravel

|

gravel-pre-coated size(mm) |

5-3 |

3-2 |

2-1 |

1-0.5 |

|

suitable aquifer |

coarse sand |

medium sand |

silt sand |

fine sand |

Table 2 Feature of Text Block

Num | Briquette Types | Filtering Material Size (mm) | Single Layer Thickness (mm) | Diameter (mm) | Briquette Thickness (mm) | Quantity (block) | Suitable Aquifer | |

① | single layer | 5-3 | 30 | 100 | 30 | 6 | coarse sand | |

② | single layer | 3-2 | 30 | 100 | 30 | 6 | medium sand | |

③ | single layer | 2-1 | 30 | 100 | 30 | 6 | silt sand | |

④ | single layer | 1-0.5 | 30 | 100 | 30 | 6 | fine sand | |

⑤ | double- layer | bottom layer | 5-3 | 15 | 100 | 30 | 6 | medium sand |

surface layer | 3-2 | 15 | 100 | 30 | 6 | |||

⑥ | double- layer | bottom layer | 5-3 | 15 | 100 | 30 | 6 | silt sand |

surface layer | 2-1 | 15 | 100 | 30 | 6 | |||

⑦ | double- layer | Bottom layer | 3-2 | 15 | 100 | 30 | 6 | silt sand |

surface layer | 2-1 | 15 | 100 | 30 | 6 | |||

⑧ | double- layer | bottom layer | 5-3 | 15 | 100 | 30 | 6 | fine sand |

surface layer | 1-0.5 | 15 | 100 | 30 | 6 | |||

⑨ | double- layer | Bottom layer | 3-2 | 15 | 100 | 30 | 6 | fine sand |

surface layer | 1-0.5 | 15 | 100 | 30 | 6 | |||

⑩ | double- layer | bottom layer | 2-1 | 15 | 100 | 30 | 6 | fine sand |

surface layer | 1-0.5 | 15 | 100 | 30 | 6 | |||

b. The single-double-layer gravel-pre-coated briquette are made in the same working condition. The double-layer gravel-pre-coated briquette consists of bottom layer and surface layer. The surface layer is made with filtering materials suited for aquifer. The bottom layer is made with filtering material coarser than surface layer. The structure, size and quantity of single-double-layer gravel-pre-coated briquette are described in Table 2.

c. The permeability testing and of single-double-layer gravel-pre-coated briquette are developed. The permeability testing involves porosity testing and permeability coefficient testing. The blocking test involves slurry blocking test and filtrate-prevent sand test.

d. The testing and test results are be contrasted-analyzed.

3 Testing and Test Methods

3.1 Testing methods for porosity of single-double-layer gravel briquette

The testing of porosity for single-double-layer gravel-pre-coated briquette adopts the briquette method. The briquette is placed in a container loaded with certain water, and measured the volume of increasing water B. The porosity is calculated according to the following equation:

η=![]() =

=![]() ×100%

×100%

where η is the porosity (%),A is total volume of briquette (cm3),B is the volume of solid part of briquette (cm3),and m is the porosity volume of briquette (cm3).

The porosity testing are conducted for all single-double-layer gravel-pre-coated briquette listed in Table 2. A highest vale and a lowest valve in the testing result is taken out, and the medium porosity valve of remained four briquettes is used as the medium porosity of the briquettes .

3.2 Testing method for permeability coefficient of single-double-layer gravel-pre-coated briquette

The testing work is conducted only at the testing instrument which measured permeability coefficient of civil engineering testing machining by oneself .The effects to the contrast analyze of permeability coefficient of double-layer gravel-pre-coated layer is very little though the acquired parameter is probably not accurate. The permeability coefficient of briquettes are calculated according to equation ① under the water temperature testing condition, and the permeability coefficient under the standard water temperature (20℃) is calculated according to equation ② :

kT=2.3×![]() ①

①

where kT is the permeability coefficient (cm/s);α is the cross section area of change head pipe (cm2);L is the thickness of briquette(cm);2.3 is the alternated factor of ln and log ;t1,t2 are the origination time and ending time of measured-readed head, respectively(s);H1,H2 are the origination and ending head(cm),and A is the volume of briquette(cm2).

k20= kT×ηT/η20 ②

where k20 is the permeability coefficient of briquette under standard temperature (cm/s);ηT is the coefficient of dynamic viscosity of water under T℃(kPa.s),and 20 is the coefficient of dynamic viscosity of water under 20℃.

As the briquettes are doused by water when testing the porosity, All briquettes are placed into electric oven under 120℃ for 24 hours before testing in order to ensure the compared property of testing data. Three briquettes are taken out randomly from each type of briquette for permeability coefficient testing. The testing of each briquettes is duplicate three times, and the medium valve of three testing results is used as the permeability coefficient of the briquette. And then, the medium valve of the permeability coefficient of three briquettes are used as medium permeability coefficient of the briquette.

3.3 Comparison of two different experiment methods of single-layered and double-layered gravel-pre-coated screen

The ①,⑧,⑨,⑩ test block in table 2 doesn’t involved in the

experiment. And the others is divided into two groups. The mud jamming test and

the sand jamming test are taken separately. The experiment facility is shown in

Fig 1.

3.3.1 Methods of the mud jamming comparison experiment

The feature of the mud is presented as follow, viscosity is 20s, gravity is 1.05, and composition of sand is 20%. Fulfill the mud tank with mud, and use high pressured nitrogen forcing the mud coming through the test block, and the pressure is 3.5 kg/cm2. And the time needed by the mud flowing through the test block should be recorded.

3.3.2 Methods of the Sand jamming comparison experiment

First we fill the mud tank with water, then we put sand on top of the test block. The volume of the sand and it’s mixed ratio should be no different in any test block. Next we use the high pressured nitrogen forcing the clean

water coming through the test block, and the pressure is 3.5 kg/cm2. And the amount of sand getting through the block should be measured.

4 Experiment Results

The result of the experiment is presented in Table 3.

Table 3 Experiment Results

|

Number |

Type |

Porosity |

Permeability |

Anti-jamming capability | ||

|

Time (s) |

Mud (L) |

sand (g) | ||||

|

1 |

Single 5-3mm |

31.68 |

0.2229 | |||

|

2 |

Single 3-2mm |

29.05 |

0.1957 |

73.50 |

4.90 |

15.70 |

|

3 |

Single 2-1mm |

25.68 |

0.1846 |

10.70 |

1.90 |

1.10 |

|

4 |

Single 1-0.5mm |

16.48 |

0.1234 | |||

|

5 |

Double 5-3/3-2mm |

29.28 |

0.2190 |

600.00 |

26.00 |

42.20 |

|

6 |

Double 5-3/2-1mm |

31.35 |

0.2073 |

349.00 |

21.40 |

15.20 |

|

7 |

Double 3-2/2-1mm |

28.75 |

0.1918 |

6.50 |

1.15 |

3.20 |

|

8 |

Double 5-3/1-0.5mm |

25.75 |

0.1696 | |||

|

9 |

Double 3-2/1-0.5mm |

30.03 |

0.1858 | |||

|

10 |

Double 2-1/1-0.5mm |

28.13 |

0.1724 | |||

5 Comparison Analysis

5.1 Comparison results of single and

double layered gravel screen

The performance comparison of single and double layered gravel screen is taken in the same aquifer, and the result is presented in Table 4.

Table 4 Result of Comparison in Single and Double Layered Gravel Screen

|

Double Layered Style |

Comparison with the single one |

Aquifer | ||||

|

Porosity |

Permea-bility |

Time |

Mud |

Sand | ||

|

Double 5-3/3-2mm |

+0.8% |

+11.9% |

+8.16 times |

+5.3 times |

+2.69 times |

Medium Sand |

|

Double 5-3/2-1mm |

+22.1% |

+12.35 |

+32.62 times |

+11.26 times |

+13.82 times |

Fine sand |

|

Double 3-2/2-1mm |

+12% |

+3.9% |

-0.61 times |

-0.61 times |

+2.91 times | |

|

Double 5-3/1-0.5mm |

+56.3% |

+37.4% |

Silt | |||

|

Double 3-2/1-0.5mm |

+82.2% |

+50.6% | ||||

|

Double 2-1/1-0.5mm |

+70.7% |

+39.7% | ||||

5.2 Result analysis

From the table 4, it can be seen that the double layered gravel screen is better than the single one in both the Permeability and the anti-jamming ability. Here are the reasons: first, it increases the comprehensive Porosity of the gravel; second, it increases the permeability by

the decrease of anti-pervious capability. The sickness of the double layered gravel is only half of that in the single one, and it has the larger diameter-grain in the underlying layer which also increases the Permeability. Third, the trumpet-shaped structure enhances it’s anti-jamming ability. Water pass-way in the double layered gravel is large in the bottom and narrow in the external, so that, it enables the inner fine grain getting out easily. And it reduces the risk of jamming of the filter. On the other hand, thinner layer makes the grain moving route shorter, and it deduces the retention time so that it creates good condition for discharging grain.

Because of unsuitable working processing, the 3-2/2-1mm style double layered filter doesn’t work well. Onetime forming way is used in the process of the test block, that’s to say, it makes another gravel layer on top of the first one without waiting solidification of the first layer. And it causes a density area in the edge of two layers. And it causes quickly jamming of the filter by the grain in a short time.

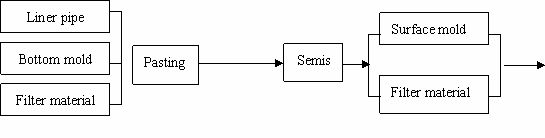

6 Molding Process of the Double Layered Gravel Filter

The Molding process of the double layered gravel filter has little different with the single one. The different is that the molding process of the double layered gravel filter needs two times molding. The major molding process is presented as below:

![]() 固化 so

solidification

固化 so

solidification

The

plastic liner double layered gravel screen is in Fig 2, and it’s structure

parameter is presented as follow:

The

plastic liner double layered gravel screen is in Fig 2, and it’s structure

parameter is presented as follow:

Screen length 1.35m

Filter length 1m

Liner characteristic Ф200×9.6mmU-PVC

Bottom gravel layer characteristic 5-3mm

Bottom layer thickness 14.5mm

Surface layer characteristic 2-1mm

Surface layer thickness 15mm

Fig

2 Plastic Liner Double Layered Gravel Screen

7 Conclusion

a. Double layered gravel filter solves the problem of low water passing way capacity and easily jamming which the former filter has. First, double layered gravel filter effectively improves the permeability and anti-jamming capacity; second, it can increase the outflow volume by discharging fine grain effectively during well development; third, it avoid the decrease of outflow during production because of it’s un-jamming structure.

b. It makes a good foundation for the development and utilization of the double layered gravel filter screen by the experimental study.